Slipform construction ascends to new heights.

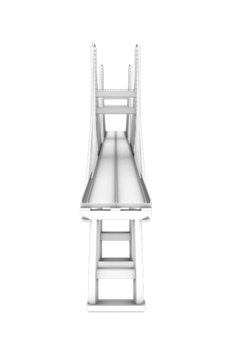

VERTICAL CONCRETE SLIPFORM CONSTRUCTION

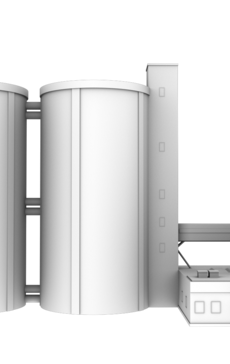

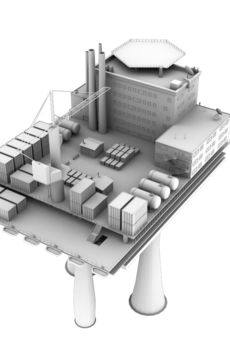

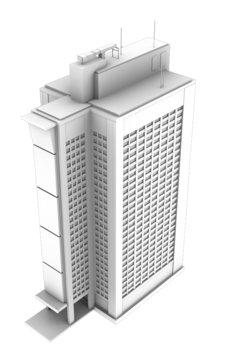

Formwork engineering at its finest: the vertical slipform system allows for the construction of jointless concrete structures, all with short construction times and high daily rates. As is the case in previous years, the slipforming method continues to be regarded as a reliable and proven formwork method in 2024, making it the go-to method for constructing towers, chimneys, high-rise cores, silos, bridge pylons and other industrial structures with exceptionally high walls made from reinforced concrete with a strong vertical orientation.

PRINCIPLE

Engineering Principles of Slipforming.

Parallel

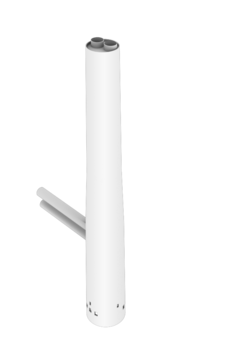

The formwork is lifted parallel to the reinforcement and surface.

Continuous

A new building is constructed by continuously adding concrete and reinforcing steel.

Hydraulic

The formwork is raised atop climbing tubes by means of hydraulic jacks.

Concrete

Concrete (15‒20 cm) is added without cold joints for monolithic structures.

Fast

The speed of construction depends on the concrete (acceleration, deceleration or even a stop is possible).

24h or 12h per day

The structure can be slipformed continuously for either 24 hours or 12 hours per day.

PRINCIPLES

PROJECTS

Our successful slipform construction projects are all over the world.

Projekte