Specialised solutions

Question the facts and make the impossible possible.

Due to various factors, such as architectural-geometric or structural requirements, Gleitbau Salzburg is often confronted with extreme situations. Whether it be a simple silo or a complicated offshore structure, finding solutions to challenging situations is our specialty.

Gleitbau’s engineers master these challenges with know-how, researching the available information on formwork technology and designing custom-made solutions. It is precisely this expertise when it comes to the practical implementation of projects that allows Gleitbau Salzburg’s teams to find innovative solutions without ever losing our crucial connection to everyday building practices.

Thousands of successfully completed projects worldwide can corroborate this ideal approach.

Examples for specialised solutions

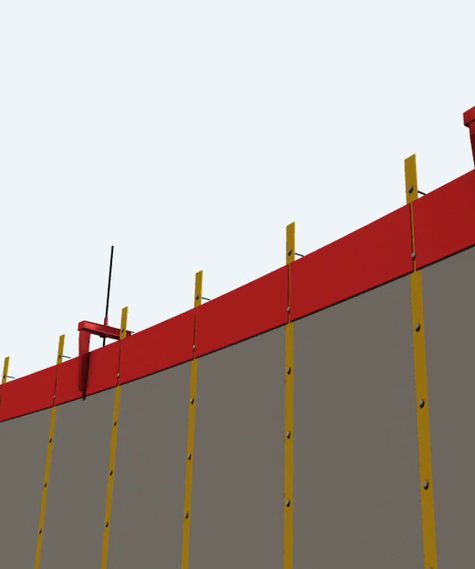

- Slipforming of LNG storage tanks using flush-mounted vertical steel elements (patented system by Gleitbau GmbH)

- Slipforming slopes in hydraulic structures

- Extended formwork solutions for silo projects (slipforming, formwork for inside hoppers, cones)

- Special formwork for shaft transitions

- Formwork for multi-use production (refractory lining works, harbour caissons, etc.)

Through individual developments in formwork and lifting technology, Gleitbau Salzburg always finds economical solutions to any problem.

Specialised solutions

LNG storage tank

LNG is an abbreviation for “Liquefied Natural Gas”. The natural gas is liquified, and its volume is reduced to 1/600 in order to facilitate transcontinental transportation and storage. To liquify natural gas, it must be cooled below -160 °C.

Huge tanks are erected at the loading and unloading docks of so-called LNG terminals to store the liquefied natural gas. These LNG storage tanks usually have a volume of approx. 150 000 m³ per tank, and each LNG terminal is made up of several tanks depending on the capacity of the facility.

The ability to build a monolithic concrete structure without cold joints, in a short amount of time, while also adhering to the highest standards of workplace safety and quality (even when faced with high wind speeds in coastal regions), proves that slipforming is the ultimate construction solution for LNG storage tanks.